|

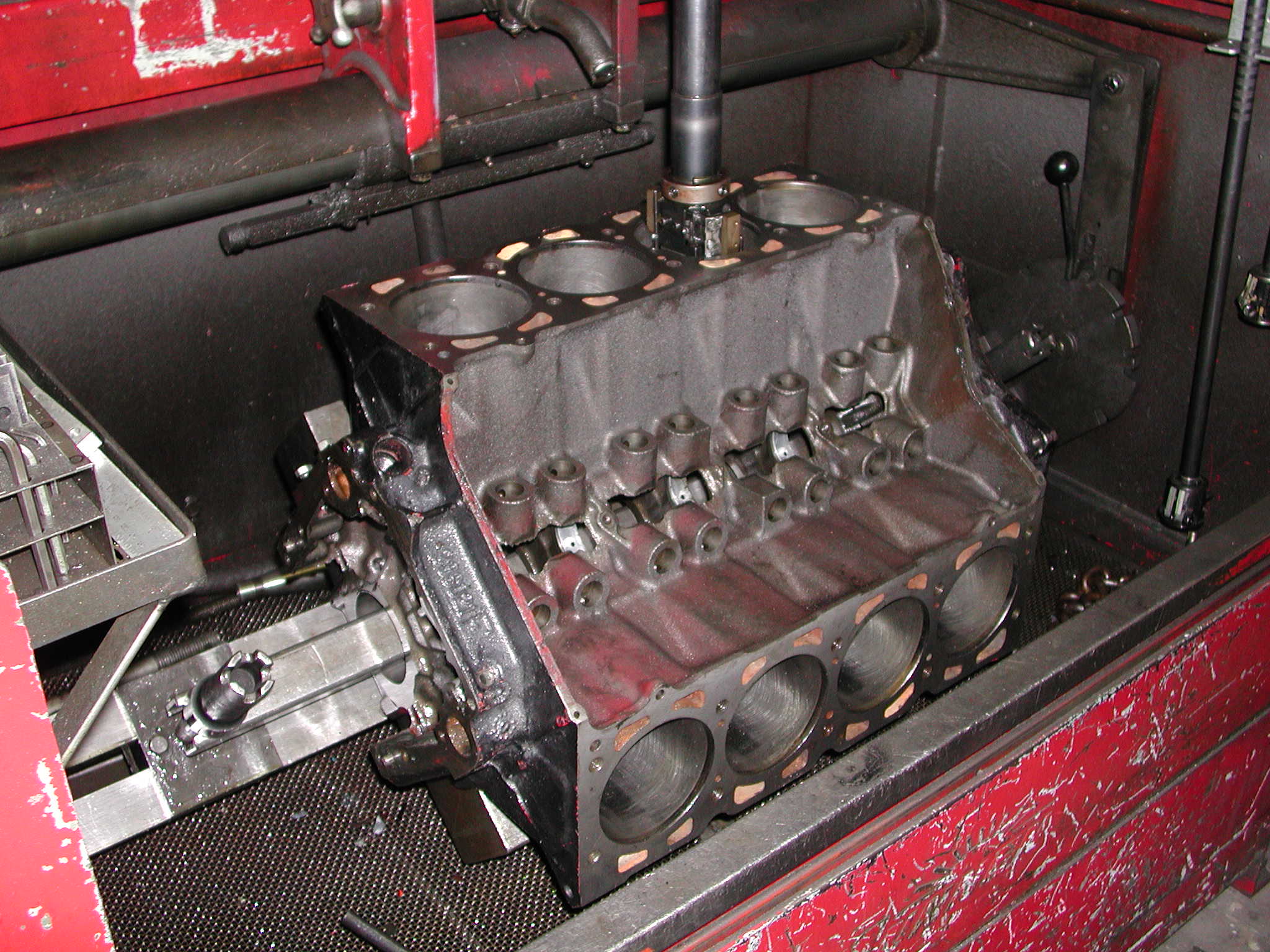

Boring of the Block

The block is mounted in the Sunnon C K-10 machine for the process of enlarging the cylinders for new pistons. The clearances are determined by the style of motor (street/race) and finish honed with the torque plates. |

|

|

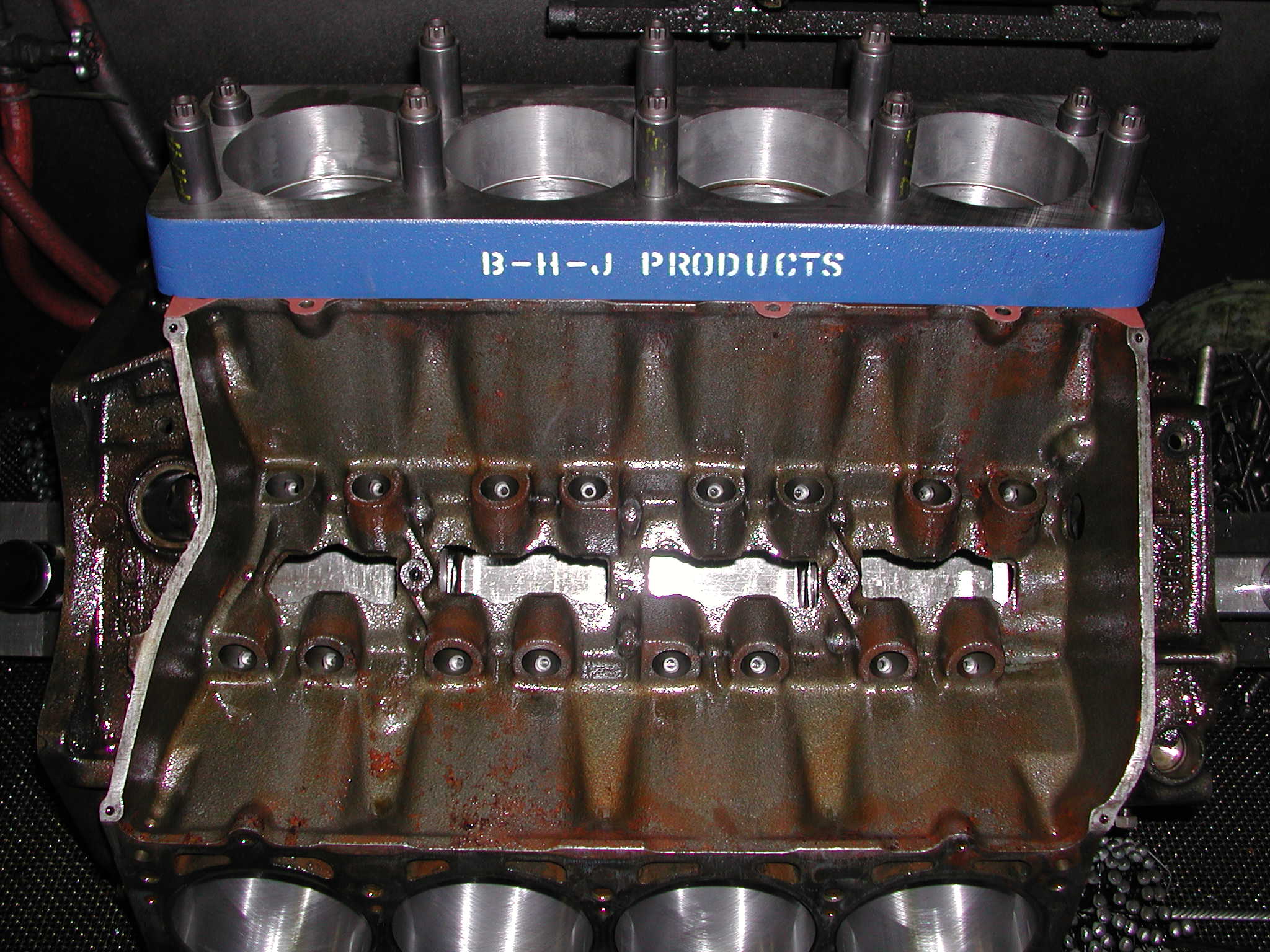

Torque Plate Hone

Block mounted in the Sunnon CK-10, using B-H-J torque plates. Torque plate simulates the head bolted and torqued onto the block, this way the cylinders are stressed under normal torque specs and the block is finish honed properly. |

|

|

Align Hone

Block mounted in the Sunnon CK-10, for honing the main bearing saddle. The mains caps are shaved about .003' and re-installed to exact torque specs and honed to factory/custom performance clearances. This gives a "true" crank shaft centerline minimizing sheer forces on the crank at high RPM. |

|

|

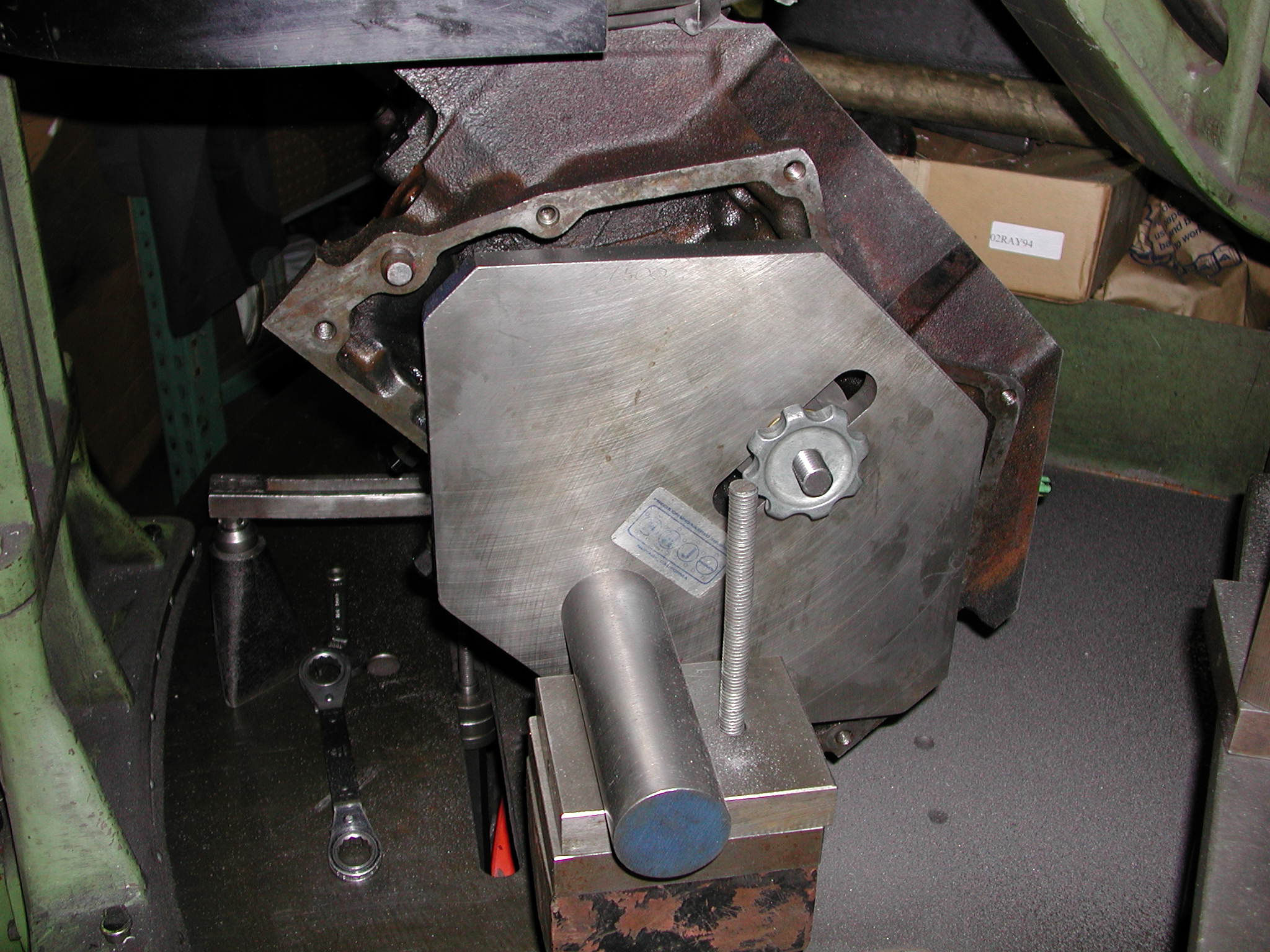

B H J Square Deck Tool

Block is setup with this tool in order to square the deck to the center line of the crank. The cylinder head deck surface is square to the crank and equal on both sides. Therefore the all of the combustion chambers maintain a precise, equal volume. |

|

|

Piston Balancing

The pistons mass is measured and then lightened to an arbitrary value. This value is the value that all of the pistons will be normalized to. In other words, they will all weigh the same hence they are balanced. This is needed to ensure that the crankshaft experiences equal forces throughout the length of the shaft. |

|

|

Rod Balancing

The rods are probably the most integral portion of the motor. They with stand the majority of the abuse as they are rotated at high RPM and experience the greatest forces from the energy created in the combustion chamber. Thus, they are prepared most intricately. First they are shaved to lighted the overall weight about 45 grams per rod. Then they are measured and shaved to exact amounts relative to the lightest rod. Last the "Big" ends are precisely balanced relative to each other. Therefore, each rod has the exact same overall weight as well as the same reciprocating mass.

The pistons are balanced as well. |

|

|

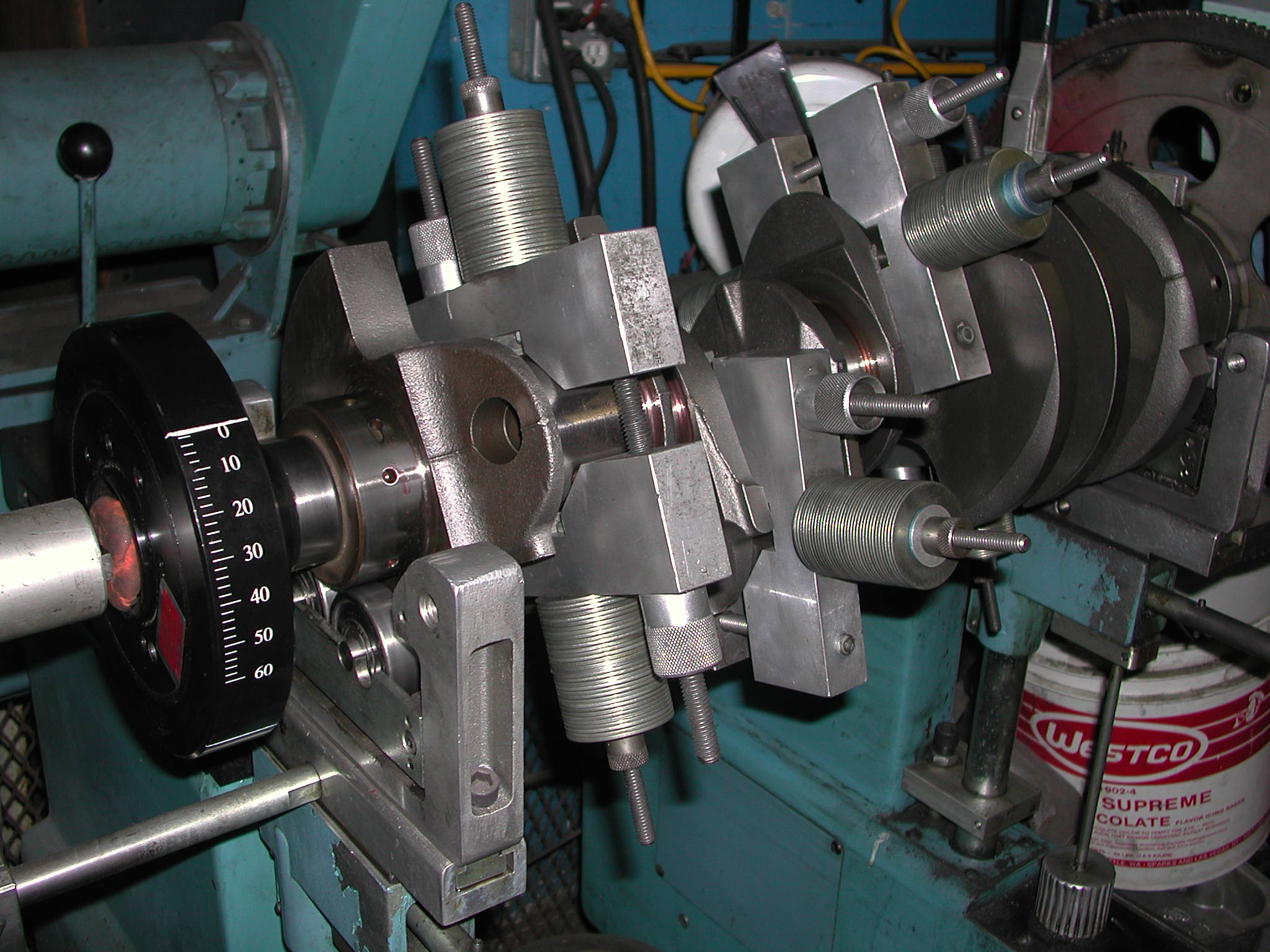

Crank Shaft Balancer

The bob weights are calculated from the rod and piston/wristpin mass. See Rod balancing. The crank is spun at about 450 RPM to analyze the centripetal forces (rotary balance), it is then drilled or welded to reduce or add mass to precise locations to minimize cyclic vibrations. |

|

|

Finished Products

This is a motor that was built with a custom ground roller hydraulic cam, 10:1 compression, Edelbrock heads, hypereutectic pistons, and a good old fashiond gear drive for style, that ran 10:80's @ 124 MPH and was driven on the street to high school. See Pictures, 64 Cutlass.

Click here for some other builds |

|